HYSIDE’S TIPS OF THE TRADE

MORE THAN EVERYTHING YOU NEED TO KNOW ABOUT YOUR RAFT!

TABLE OF CONTENTS

OVERVIEW

Since 1982, HYSIDE has been synonymous with the most durable and longest lasting inflatables on the planet. Through the industry’s most durable fabric and the use of the newest technologies, we’ve designed these boats to be the workhorses for the commercial outfitting industry. We’re certain you will enjoy your boat as a worry free source of FUN for years.

In this manual, you’ll find a comprehensive assembly of tips and instructions on using and caring for your new inflatable.

BOAT ANATOMY

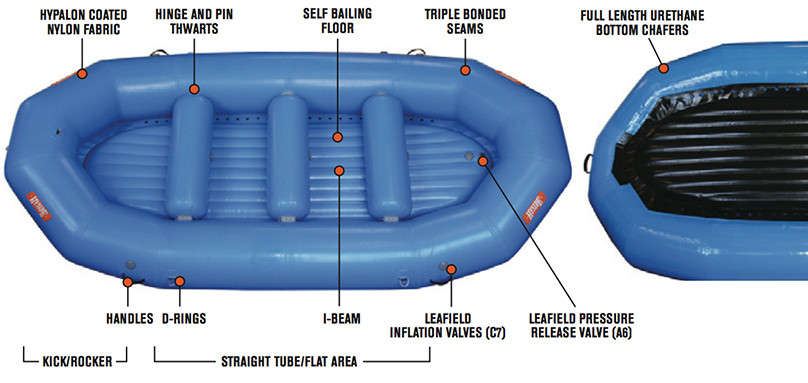

BOAT ANATOMY

The goal of this section is to give you a simple explanation of the parts of your boat and how they function and operate. Getting to know your boat inside and out is the first step to caring for your inflatable. See below for a brief list of terms and parts on your HYSIDE:

SELF-BAILING RAFT

STANDARD FLOOR RAFT

Includes all of the features the self-bailing raft has, with the exception of the floor type and fixed thwarts.

VALVES

VALVE TYPE

VALVE TYPE

Your boat consists of multiple air chambers, each with its own valve. There are two types of valves we are currently using:

The inflation valve (Leafield C7) and the Pressure Release Valve (Leafield A6). They are very durable and simple to use. Pre-2000s Hysides were equipped with Metal Military Valves and Halkey-Roberts Pressure Release valves. We still stock these as well.

THE INFLATION VALVE (LEAFIELD C7)

The inside center of the valve has a spring loaded stem with a flat plunger on the bottom. When inflating, make sure the spring isn’t held open. You can do this by pushing the spring down and to the left (counterclockwise). This will make sure the valve is closed, so air can only pass through into the chamber. In order to deflate, you will need to push the stem down and twist it to the right. This will hold the spring in the open position to allow the boat to fully deflate. Make sure to always keep the valve cap on, when not inflating/deflating. This will protect the stem and keep debris out. There are replacement caps available should you lose any.

THE PRESSURE RELEASE VALVE – PRV (LEAFIELD A6)

Unlike the round design of the tubes, which distribute increases in pressure evenly, the floor’s mattress design is smaller and less forgiving with more drastic pressure changes.

We equip our floors with PRV’s designed to release at 2.0 PSI.

NOTE: The old leafield pressure release valves were color coded and blue indicated a 2.0 PSI valve. The newer valves have the PSI engraved in the valve itself. So if you can’t determine the color dot, it is a good indication that it is a very old valve and needs to be replaced.

VALVE INSTALLATION

VALVE INSTALLATION

Valves come pre-installed on your boat, direct from the factory. If for some reason you have to remove/re-install the valve, here’s a detailed instruction. Both the C7 and A6 Leafield valves are very similar to install. Both have a female part inside the boat, then an outside washer and male part.

THE INFLATION VALVE (LEAFIELD C7)

Push the male/threaded part of the valve through the valve hole opening in the floor or tube. Grasp the valve base firmly and thread the valve together making sure that the boat fabric does not twist as the valve is tightened. Hand tighten the valve, then finish tightening with the provided valve wrench after the tube is inflated to operating pressure. Removing the valve would be the exact opposite, just remember that the female base in the boat is free floating!

Cleaning your Inflation Valve

The most common causes of leaks are from valves. If your valves are not airtight, dirt and grit can work its way into your valve, causing an improper seal (leak) and cleaning the valve will usually solve the problem. First, deflate the tube of the valve needing to be cleaned. Next, quickly depress the spring up and down a few times and use a pump to blow bursts of air into the valve while it’s in the open position, to help dislodge any debris that might be holding the spring open. The valve seal at the bottom of the valve stem should be free of debris, as this creates the seal. Once done, reinflate the tube and test. If still leaking, remove the valve for a more thorough cleaning. (See Valve Installation)

THE PRESSURE RELEASE VALVE (LEAFIELD A6)

The PRV’s base inside the floor is free-floating. To install, work the base into position so that the collar of the base protrudes through the opening in the floor. Line up the valve with the hole in the floor. Insert the male/threaded part of the valve into the hole of the floor.

Cleaning your Pressure Release Valve (PRV, A6)

Your pressure release valve is a great little insurance policy for your floor. Designed to release pressure at 2.0PSI, if working properly the PRV will help prevent costly damage to your floor from drastic pressure changes or over- inflation. But the thing is, it has to be working properly!

Never plug a PRV if it is leaking! Either clean or replace the valve.

Because of the location in the boat, the PRV will usually need more attention and cleaning than the other valves. Sand and grit can cause the PRV to function improperly, either leaking air or not releasing at the appropriate pressure like it’s designed to do. To clean your PRV, simply unscrew the valve with your star-shaped end of your valve wrench. Next wash the valve in warm, soapy water, pressing the spring up and down as you wash and rinse. This should dislodge anything that might be hindering the spring from operation properly. Next, reinstall the valve by hand tightening. Make sure the valve is aligned around the floor fabric. Once aligned and hand tight, tighten with your valve wrench. Next, you’ll want to reinflate your floor and test for leaks (spray with soapy water and watch for air bubbles). NOTE: If the valve is leaking from the perimeter of the valve, it is either not aligned properly or it’s not tight enough. Unscrew, align and retighten to be sure. If the valve is leaking from the inside/ spring area of the valve, there’s still something holding the spring open, requiring a more thorough cleaning. Repeat steps above, reinstall and retest.

Grasp the valve base firmly and thread the lock ring onto the valve making sure that the floor fabric doesn’t twist as the valve is tightened. Hand tighten, snug with the valve wrench, then finish tightening with the wrench after the tube is inflated to operating pressure. Removing the valve would be the exact opposite, just remember that the female base in the boat is free floating!

(See TROUBLE SHOOTING for tips on leaky valves and maintaining valves).

THWART INSTALLATION

We’ve made it very simple to install and remove your thwarts. Like a door hinge, the two hinged knuckles connect with a pin. Removing is simple, just remove the pin! You might need pliers to grab the pin when removing.

Older model HYSIDEs were outfitted with lace-in thwart attachments. We still stock lace-in thwart attachments as an option, as well as fixed attachments. The knuckles can also be installed at various points in your boat to allow for multiple setups, depending on your use! See “gluing instruction” on how to install knuckles.

For instructions on lacing in our older lace-in style thwarts, check out this video…

For instructions on lacing in our older lace-in style thwarts, check out this video…

FLOORS

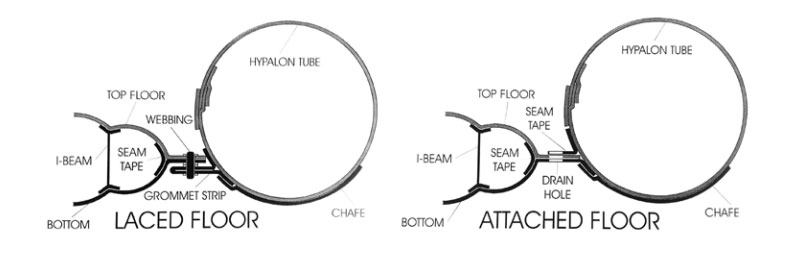

FLOOR TYPES – SELF BAILING VS. NON SELF BAILING

FLOOR TYPES – SELF BAILING VS. NON SELF BAILING

The main difference between a standard and self bailing floor is that standard (non self-bailing) floors are sealed to the outer tubes, whereas the self-bailing floor is inflated and is either laced in or glued in, with holes installed around the perimeter, allowing the water to exit. The floor of a self bailing raft is a wide flat inflated chamber. When inflated, the floor is about 5 inches thick, so the top surface of the floor is above the surface of the water. When water splashes into the raft, it flows across the floor, down over the edge of the floor, and out through the lacing.

FEATURES OF A NON SELF-BAILING FLOOR:

- If running Class I or II whitewater the inside of the boat/floor boat should stay dryer

- Requires a bucket to bail water

- When water enters, the boat becomes heavier and less maneuverable

- Chances of getting stuck on a rock is more because they are heavier with water in the boat

- Costs less than Self-Bailing floors

Most of our raft line-up nowadays is self-bailing. Our entire Kayak line is self-bailing, as well as our Outfitter and Outfitter Pro Raft series. Running extreme whitewater is safer and easier with a self-bailing floor and other benefits include a dry floor for passengers as well as a more firm floor to stand on or fish from.

FEATURES OF A SELF-BAILING FLOOR:

- Does not require buckets or pumps to remove water

- Much more maneuverable since any water splashing in quickly exits (in a few seconds)

- Less likely of getting stuck on a rock because the boat remains lighter

- Makes a nice mattress when flipped over

- More expensive than ‘Standard’ non-bailing floors

INFLATABLE FLOOR ATTACHMENT TYPES

INFLATABLE FLOOR ATTACHMENT TYPES

Inflatable floors are either glued in or laced-in with webbing, through grommets, when attached to the main tubes. We transitioned to the “attached” self-bailing floor back in 2000 for all stock models, due to ease of use and maintenance for the customer, however, we still produce Lace-in floors, especially for international clients who need to break down the boats for transport.

FLOOR VALVES

FLOOR VALVES

All HYSIDE inflatable floors are equipped with a Leafield A6 Pressure Release Valve (PRV). This PRV is an added insurance policy against over inflation. The PRV we place in our floors is built to release at 2.0 PSI (blue dot). Please note that there are other PRV’s with higher pressure releases! This can void your warranty if damage is caused to the floor from using a PRV with higher PSI than recommended.

PREVENTIVE CARE AND MAINTENANCE

Your HYSIDE inflatable was designed to withstand the everyday abuse from Commercial Outfitters.

We’ve designed our boats to be very dependable and very simple to use and operate, even in the toughest conditions. Here are some in-depth tips and processes to keep your HYSIDE running in tip top shape for DECADES, like many of our happy customers have reported.

INFLATING YOUR HYSIDE

INFLATING YOUR HYSIDE

Your boat consists of multiple air chambers. When inflating your raft or boat, fill each air chamber in a clockwise pattern around the boat, just until the craft takes shape. Then work your way back around the boat filling the chambers to the pressure level indicated for that particular boat.

Each chamber has a cone shaped baffle that separates it from the others. Maximizing pressure on a single baffle can easily damage it; therefore equal amounts of pressure should be applied to each chamber until you reach maximum pressure.

To inflate your boat, a hand, foot or electric pump can be used. A low pressure pump (designed specifically for inflatables) is best, as we recommend a max pressure of 2.0 psi in the floor (Self-bailing models only) and 3.0 psi in the tubes. If the floor of the boat is inflatable, add air until the pressure relief valve releases a small amount of air. Use caution when inflating the floor! The pressure release valve can only release air so fast, so if the air flow is faster than the release of pressure, you could cause damage.

Also consider super heated surfaces, like asphalt and sand. They have temperatures that far exceed the air temp and can cause the boat pressure to exceed recommended pressure within minutes.

Most boats that come in for floor repair typically have a plugged or non working PRV, or the user was forcing the air in faster than it could release, after it was full.

A rule of thumb for gauging the proper pressure for the tubes is to push down with your thumb at the center of the tube. If you can deflect about a half an inch from the top plane of the tube, it will be close to 3.0 psi.

Don’t overfill. A properly inflated boat should have just a bit of give.

Be aware that air temperature causes changes in the air pressure in the inflatable chambers. Many boaters fill their boats in the morning when the air is cool, but as the temperature increases over the course of the day, the air in the tubes expands, increasing the pressure. If a tube or chamber becomes too pressurized, it can explode if struck by a sharp object. You may have to let some air out at different points throughout the day if you operate your inflatable in the hot sun.

DEFLATING YOUR HYSIDE

DEFLATING YOUR HYSIDE

The preferred way to deflate your inflatable is by deflating all main chambers simultaneously, as this will help avoid stress on any one baffle (get a friend to help). You can then move on to deflating the thwarts and floor. To set the valves for deflation, simply push the valve stem in approximately 3/8” and turn it about ½ turn until it locks in the open position. You can use the bottom side of a pump to suck the remaining air out of the chambers.

CLEANING YOUR HYSIDE

CLEANING YOUR HYSIDE

Keeping your inflatable clean, especially prior to storage, will help prolong the life of your craft!

Sand and gravel can cause abrasion and plug air valves. If left to soak into an inflatable boat, salt water can cause the material to deteriorate.

You can use soap and water to clean your boat. Rinse the boat off with a power washer then spray the cleaner on and wait five minutes. Using a circular motion, scrub the area and then fully rinse and dry.

STORING YOUR HYSIDE

STORING YOUR HYSIDE

REMOVING WATER

Preventing moisture during storage will greatly increase the lifespan of your boat.

Over time, moisture inside the tubes can break down the glue joints, so it needs to be removed promptly. The obvious signs of trapped moisture are hearing it sloshing around or rubbing the two sides of a deflated tube together and if it feels slippery/slimy inside, you probably have old moisture inside (part of a routine inspection).

Removing the valve to the chamber is the first step in cleaning it out. Use a pulley or turn the boat to the required position and tie it off. The goal is to position the boat where you can get excess water to pool, then use a shop vac with a hose outside in the sunlight. Next, tape a 1⁄2 inch piece of PVC hose to the end of the hose and stick it in the chamber, use this to remove all remaining pooled water. For the remaining moisture in the tubes, turn the

boat upside down and place the boat in the sun (black bottom heats in sun)

Using the same PVC pipe, reverse the flow of air with the vacuum and blow air into the floor. The hot air will circulate and evaporate it until it is completely dry.

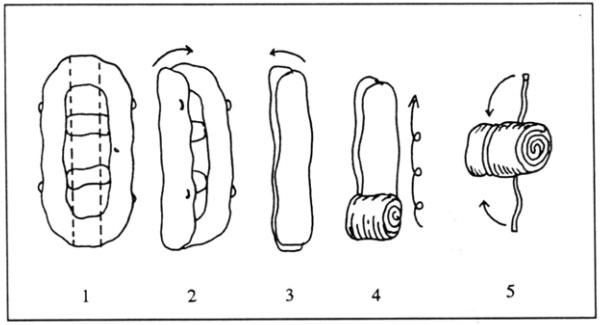

ROLLING YOUR HYSIDE

ROLLING YOUR HYSIDE

ROLLING YOUR BOAT IS VERY SIMPLE.

- Lay the boat out flat and deflated, making sure to remove any straps or equipment.

- Start your fold length-wise and fold inward towards the middle.

- Depending on the size of your boat and how tight you want to roll for storage (packing it for a trip or just storing in a closet for winter), will determine whether to fold the boat in thirds, or just in half.

- Once you’ve folded the boat length-wise towards the center, start rolling at the end opposite of the floor valves (this will allow air to continue to escape as you roll) and roll until it’s a nice little rubber burrito.

- Cam strap from there and you’re done!

SHORT TERM STORAGE

Wipe down, partially deflate (1 PSI) and cover with tarp. If this is not possible, completely deflate the boat and be sure it is dry and clean before rolling and storing. If you plan to store your inflatable boat on a trailer, be sure there are no bends or kinks in the boat.

LONG TERM STORAGE

After the season, rinse off any dirt/grime and allow the boat to FULLY air dry.

Moisture can get caught in the tubes and floor, so make sure to let it air dry completely!

Store the boat in a cool, dry place out of sunlight. Ideally, storing the boat partially inflated is the best, but if space is not an option, you can definitely roll it up as tight as needed. Do not store directly on concrete! Moisture and mold will transfer onto the boat and cause permanent staining. Put a pallet down or something in between to reduce moisture transfer. Store your inflatable off the ground, out of reach of rodents, as they have a fondness for chewing holes and nesting in inflatable material.

TRANSPORTING YOUR HYSIDE

TRANSPORTING YOUR HYSIDE

The bonus with our Hypalon material is that it’s easier to roll than other boat fabrics, it’s lighter and is less likely to get damaged in transport. That said, there are still some precautions to take when transporting your boat.

STANDARD PRECAUTIONS

Because punctures are the main concern with inflatable boats, it is important to protect it from sharp objects. Use care when transporting knives, fishing hooks, and other objects that could puncture the skin of the inflatable boat. Watch for sharp metal or branches when navigating the waters, as well as avoid dragging the boat over rocks and debris when landing on a beach.

Even dull objects such as oars, ropes, or coolers can cause abrasion and deterioration of the coating material if allowed to rub for an extended period of time.

Make sure all valve caps are screwed on prior to rolling. Roll the boat as tight as possible, cam strap it secure and package in the smallest box possible (if shipping). This will avoid damage during transit and will save on freight if you are shipping it. If too big for a box, wrap the boat in a tarp, canvas, or HYSIDE Boat bag. Be sure not to load other equipment on top of the boat that could potentially wear on your boat.

Moving the boats has been known to cause more damage than usage on the river unless closely monitored. Using the handles as tie-downs, abrasive ropes rubbing on the tubes, and the biggest culprit of all, tossing the boats to the ground!

RESTORING YOUR HYSIDE

RESTORING YOUR HYSIDE

As time goes on and your boat has been beaten by the sun and the various adventures you’ve put it through, here are some tips to bring your HYSIDE back to life:

WORN AREAS

Areas where there is constant wear, a patch is the easiest and most affordable way to enforce the area. In most situations, you may be able to stop the cause if it originated from improper trailering or dragging of the boats. If you are looking to enforce a larger area of the boat we recommend taking it to a professional raft repair facility or using System 6 Urethane Coating. If you choose to apply the paint yourself, first clean the surface with MEK using a cloth. Then build-up thin layers of paint using the same process explained in gluing: short bristle paint brush and multiple thin coats.

REMOVING LOOSE THREADS

The aging of a boat will always produce frayed ends from the nylon base cloth. You can cut the ends off with scissors and then finish it off by waving a heat gun over the clipped area. This step not only removes them from sight, but reduces the chances of future fraying.

If the seam tape, handle or D-ring bases are heavily worn, you can clip the frayed edges and then use a Dremel tool to bevel the edges and then flash it with a heat gun.

TIPS FOR OUTFITTERS

This section is a more in-depth guide for Outfitter’s fleet care and maintenance.

Most Outfitters would agree that over 90% of the wear and tear of rafts occurs off the river. How you care for your rafts and what systems you use for transporting and taking your raft in and out of the water will determine the life expectancy of your fleet. In direct proportion to the above will be your profits, down-time, maintenance expenditures and stress level. The following information has been broken up into four categories:

- Handling

- Maintenance

- Repair

- Storage

HANDLING

HANDLING

The most damage that occurs to a raft is during handling. Whether you are taking rafts to the put-in inflated or deflated, the following applies:

- Do not tie down the rafts with a rope. The vibrations and movement on a trailer or back of a truck will cause the rope to abrade away the raft coating, oftentimes right down to the nylon.

- Be very alert to any abrasion if you are running webbing over the rafts during transportation. A wide soft webbing is preferable. Probably the ideal method is 2” webbing running through a 10’ length of fire hose. The fire hose stays in one place while the 2” webbing could slide back and forth.

- When transporting large numbers of boats deflated on a truck bed or trailer, try to stagger the “stack” so that valves, D-rings and rubber motor mounts do not pile up on top of one another to cause pressure points.

- Be careful to look for any surfaces that may come in contact with the rafts during transportation. This includes wheels, wheel-wells, bolts, etc. Close attention to the above should eliminate 30%-40% of your repair expenditures.

- Putting the raft in the river and taking it out is probably the second leading cause of raft damage. Never drag the raft on cement or gravel. Carry the raft until it is in the water. Instruct your crew as to the importance of this rule and let them know that you won’t tolerate dragging rafts.

- Use a tarp, tables and pads as a surface where boats are rolled up. This helps keep sand and mud out of valves and out of rolled boats while they are being transported.

MAINTENANCE

MAINTENANCE

Preventive maintenance is your best tool in keeping your fleet on the river.

- Whenever possible, store boats under a shelter, out of the sun’s harmful rays. Never let boats unnecessarily bake in the sun.

- Relieve air pressure when not in use.

- Store boats unrolled if possible

- Always wash boats down after and between use to get rid of sand and grit that can damage seams and clog valves.

- Number the boats and routinely pull them for inspection throughout the season. You’ll begin to notice and prevent problems like trailer abrasion and drag marks. Remember, catching a problem before it causes downtime will save you considerable TIME, MONEY and CUSTOMERS. In addition, inspect your boats at the end of the season for wear and tear.

REPAIR

REPAIR

If repairs are required, DO NOT WAIT until spring to get your boats fixed. Be sure to inspect all of your repair materials prior to the start of a new season, especially your adhesives. Adhesives usually have a one-year shelf life so it is important to bring in fresh materials every season. Without discussing the technical aspects of repair, let’s discuss the overall concept of repair.

- Minor repairs are easily made at your place of business only with the proper equipment. An investment of less than $100 will buy you proper glues, solvents, grinding wheels, rollers, etc. We regularly stock everything you need for boat repair and maintenance.

- Cosmetics are critical to raft repair. Your clients may not return if they see rafts have sloppy repairs. Repairs must be of the same color fabric. Properly cut and rounded patches and all excess glue cleaned off from around the repaired area.

- Major repairs will most likely need to be completed at a repair facility. If the raft needs to be returned to service quickly, call the repair facility and advise them of the problem. With advance notice, they can set aside time to do your repair promptly and return the raft on schedule. If you have enough rafts to cover your needs, set aside major repairs until the end of the season. It’s usually a good investment of 10% to 30% of a new raft to recondition your raft at a quality repair facility. Generally the work performed comes with a one year warranty. Call us for a list of authorized repair centers in your area or checkout hyside.com.

STORAGE

STORAGE

As mentioned under “Storing your HYSIDE”, rafts should be stored clean, dry and out of the sun. Wash the raft at the take out to get rid of sand, sticks, etc. and allow the raft to dry upside down in the sun. After the bottom is dry, turn the raft over, wipe out excess water with a sponge and allow the inside to dry (in hot weather, this will only take a few minutes). After the raft is dry, store out of the sun. UV rays are your worst enemy. Store in a building or under an awning. Never allow rafts to bake in the sun.

Occasionally, water may enter the inside of the tubes. This water must be removed immediately and the inside dried. Moisture will eventually deteriorate the glue around the seams, so make sure boats are dry when stored. Remove the inflation valve and pour out all the water possible. Insert a 1/2” hose to the end of the air chamber and connect it to the exhaust hose of a vacuum cleaner. Let the vacuum cleaner run for one hour or more to remove all moisture.

During the off-season, rafts may be stored inflated or deflated. It is best not to roll up the raft during the off-seasons as this may eventually cause cracks in the material. When deflating, open the air valves and deflate one raft on top of another. Do not suck the air out and close the valve, this again may cause cracks in the material. A word of caution: Do not store on cement (because of moisture) and put plenty of bait out for mice and rats (they love to chew on and nest in your rafts),

ADDITIONAL SUGGESTIONS

ADDITIONAL SUGGESTIONS

Designating a specific inspection area with all the necessary tools available will facilitate the frequency of your inspection routine.

- Whenever possible, transport inflatables on the top of the load, inflated, or by themselves. No coated material can withstand the constant grating of a hard object and sand or dirt down miles of dirt road.

- Train crew to wet down straps before they are pulled through frames. A wet strap will not cause abrasion to Hypalon or Neoprene.

- Be aware that rodents will eat coated fabrics that have food substances on them, especially in winter. Keep your boats clean.

- Placing talc inside the tubes of your boat will help prevent rot and mildew build-up during the off-season.

REMEMBER: Your boats are a reflection of your operation. Leaky, beat up, less than topnotch boats will result in lost customers, poor guide morale and most importantly, less cash in the bank. The results of a daily maintenance schedule and a year-end repair and refurbish program will be boats which impress your clients, boats which will impart confidence to your guides and boats whose repair costs will hit you a little at a time, rather than all at once.

REPAIR

Many manufacturers recommend that you bring your boat to a professional for larger repairs, because it can be difficult to get a good seal with a patch. However, if you have a small puncture, want to add-on D-rings/Footcones, or are in a situation where you need to make immediate repairs, follow the directions below

LOCATING A LEAK

LOCATING A LEAK

Sometimes, even with the best care and safety precautions, your inflatable boat can develop a leak. Unless you have a major and obvious accident, it may be difficult to determine the location of the leak. Never assume there is only one leak. Check the entire boat with soapy water to be sure before setting out on the water. More often than not, a leak comes from a loose valve or an old patch that was applied incorrectly.

With the boat inflated, start at the valve and spray with soapy water, watching for bubbles to form on the surface of the boat, as a result of escaping air.

If the leak is coming from the outskirts of the valve, it is either loose, the washer is upside down or the valve is off center. Simply remove the valve, readjust and re-tighten.

If it leaks from the center, something is holding the spring open (usually silt/sand). Remove the valve, wash with soapy water, making sure to depress the spring several times to free any debris. Once you re-install the valve, check for leaks again. Refer to the Valve section for complete instructions to install/remove.

If the leak is in the fabric, patch with an appropriate sized piece of fabric following the Gluing Instructions on the next page.

REMOVING AN OLD PATCH

REMOVING AN OLD PATCH

Pulling off an old patch is identical to replacing a broken handle or D-ring. You simply take the heat gun and wave it over a corner at low heat until you are able to lift the corner with channel lock pliers. Then work the heat gun down the patch until you pull the whole thing off. Be careful not to apply too much heat to one location or it will blister.

Once it is off you will need to clean the surfaces. If someone left you with a mess, you may need the more aggressive buffing wheel (item # 125G). But be extremely careful not to remove too much Hypalon, all you need to do is remove the glue. If you ever need to repair the area again, you’ll want to have some Hypalon to work with.

LOOSE EDGES

LOOSE EDGES

If you have a loose edge on a footcone, handle or D-ring patch and wish to tack it down, pull up on the loose edge until you find good adhesion. If more than ½ of the surface area pulls up easily it will be necessary to completely reinstall the item.

COMMON TOOLS FOR REPAIR

COMMON TOOLS FOR REPAIR

Below are some common tools for repairing your inflatable. Most of the items you’ll need can be found on our website. A small repair kit is included with new boats that feature a valve wrench tool and small patches.

HYSIDE DELUXE REPAIR KIT

The repair kit includes everything you need for a solid repair on or off the water. It includes fabric (color of your boat), a 4 oz Stabond 2 part adhesive, sanding wheel, brush, and a Leafield Valve Tool.

ROLLERS AND WHEELS

Use Rollers to compress the fabric materials together during a glue job, to ensure a solid bond. Standard Compression Roller is ACC-114. Ergo Roller (blue) is ACC-112.

The black wheel is for cleaning up after a glue job. ACC-125K

The orange wheel is for standard buffing and prep work. ACC-125O

The gray wheel is aggressive, for heavy duty jobs like removing old glue. ACC-125G

You can also use Dremel tools, especially for detailed areas, like just around the patch’s shape when prepping a boat for a D-ring/Handle. Use Dremel Grinding Stone #952.

GLUING INSTRUCTIONS

FOR STABOND

To ensure success when attempting glue repair, please keep in mind that planning and preparation prior to applying the glue is 90% of the effort.

PREPARATION

- Calculate size of patch (usually 2 inches larger than tear, all the way around).

- If attaching D-rings or handles, chamber should be inflated. If repairing a tear or installing footcones, deflate air chamber and place on a flat, firm surface. Make alignment marks on both the surface and the patch at 12-3-6-9 o’clock positions, so you can see where to sand and where to line up the patch when applying to surface. (Use a grease pen or pencil for easy removal).

- With 80 grit sandpaper, lightly sand both the patch and surface, only enough to remove the sheen. If you are replacing a patch, be sure both surfaces are free of old glue.

- Make sure room is well ventilated. Install fan if necessary to remove fumes. CAUTION: The mixture is flammable and contains Free Isocyanate.

- For Hypalon repairs, use Toluene to clean the material and open up the pores of the fabric. Any PVC materials, like our Hinge and pin Thwart Attachments, should be cleaned with MEK. If not available, you can use acetone or rubbing alcohol.

MIXING GLUE

We chose 2 part glue because it has a faster set up time and a much stronger adhesion.

Glue mixing is required. Stabond UK-148 consists of both a resin (clear in can) and an activator

(brown in bottle).

TIPS:

- When humidity is over 55%, DO NOT attempt to glue. Apply glue indoors for best results. If outside, WORK IN THE SHADE, as direct sunlight will speed dry time.

- Mixing in a glass jar with a cap is the best method and use a stick when mixing.

- If glass jar not available, you can use a tuna can, but keep in mind you may need a cap.

7. Calculate the amount of glue needed.

- 4 ounces will cover approximately 2 sq. ft. with 2 coats

- Each size comes pre-measured with 8 parts resin to 1 part activator. (1 can to 1 bottle, ½ can to ½ bottle and so on). Mix appropriate amount of activator and resin using a mixing stick.

- MIXED GLUE ONLY LASTS 4 HOURS WHEN CAPPED AND PLACED IN A COOL DRY PLACE. After each use, seal remaining UNMIXED glue preferably in glass. This should last the remainder of the shelf life (1 year). (See Storage section for best results.)

APPLICATION

TIPS:

- Most common problems arise from putting too much glue on any one surface during application. Thick heavy coats will actually create LESS of a bond between the fabrics, so go with two light coats!

- Make sure you plan for no interruptions during the application.

- If available, get an egg timer to keep drying time consistent. The longer you take, the faster the base of the glue will evaporate, making the glue thicken.

- Cut bristles on brush down to 1/2 inch to assure a stiff end, to hold less glue.

8. Apply a thin coat of glue to both sanded surfaces using brush. When applying, use the brush as more of a squeegee to push a thin layer across the entire surface area. Wipe the excess glue back into the can.

9. Let first coat dry for minimum of 20 minutes depending on temperature and humidity, or to a non-tacky state.

10. Apply a second coat to both surfaces and let stand until slightly tacky. (approx 5-10 minutes depending on humidity). Alternatively, you can wait for the second coat to dry (20-30 minutes) and use a heat gun to reactivate the glue. This will also help make both sides malleable and flexible for compression.

PATCH PLACEMENT

11. While the glue is still tacky (or after reactivating with a heat gun), carefully line up patch with marks you’ve made and press both surfaces together firmly. The patch should be applied on a firm surface so you can use your weight to ensure the two surfaces have made contact. This is particularly true when you have something like a D-ring that has multiple layers of materials fabric and webbing to flatten.

12. Fully deflate chamber and place on firm surface. (If repairing a tear or installing footcones, you’ve already done this). Using a roller, roll all areas of the patch to ensure surface contact to all areas. Working from the center towards the outside, use the roller to work out any wrinkles or bubbles.

TIP:

- If your patch goes down crooked or wrinkled, use a heat gun to re-activate the glue making it easier to remove and reapply.

- DO NOT PATCH OVER A SEAM. Seam leaks travel, so lift the seam and find the origin of the leak.

CLEAN UP

13. When gluing, it’s okay to go over the lines, but you want to make sure to remove the excess glue within 24 hours, before it turns brown. There are a couple options:

- Using a soft nylon wheel and drill, remove excess glue from the surrounding area of repair. Make sure the direction of the spinning wheel spins outward, away from the patch, so you don’t lift an edge.

- You can wipe the excess glue with MEK, but don’t soak it or it may seep into the edges and loosen the glue bond.

STORAGE

Keep glue stored in a dry area at room temperature. Date bottom of can and replace annually. You can re-use the brushes if they are stored in MEK in a jar that has a hole in the lid large enough to slide the brush in. Use aluminum foil to fill any gaps.

REPLACEMENT PARTS

REPLACEMENT PARTS

We normally stock most replacement parts for your inflatable, like D-rings, Handles and Footcones.

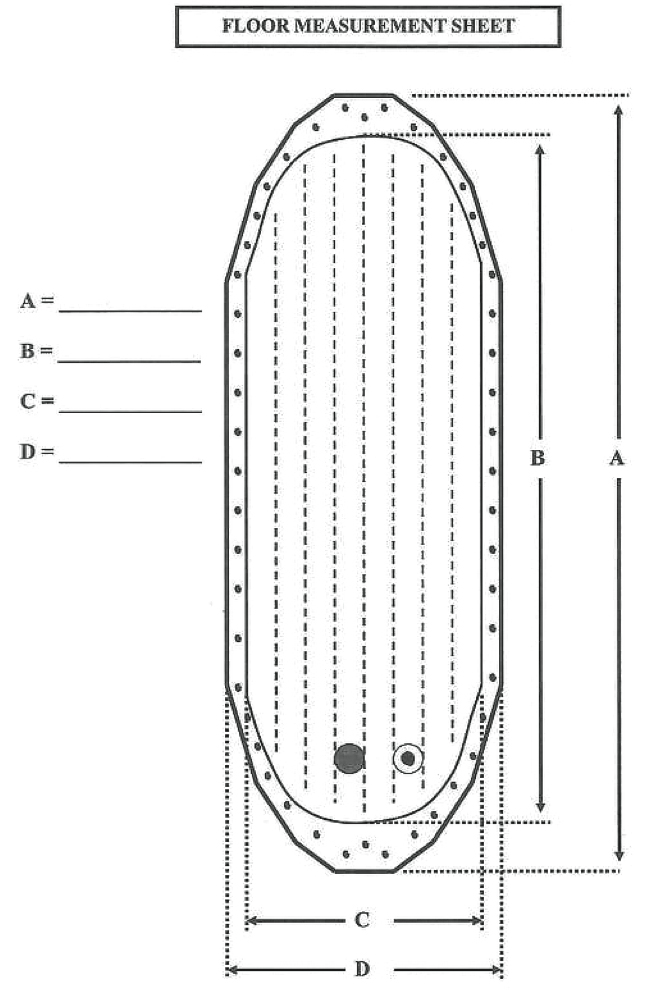

Since the boats are handmade, the two parts that are not normally stocked are replacement floors and thwarts (since the measurements can vary slightly). If you need a replacement floor or thwart, we need the following measurements listed in the diagram(s) below, when you place your order. The best time to order is from Late Summer to December, for delivery the following spring, if you need it by the start of the season.

Measure floors while deflated, measure thwarts while inflated.

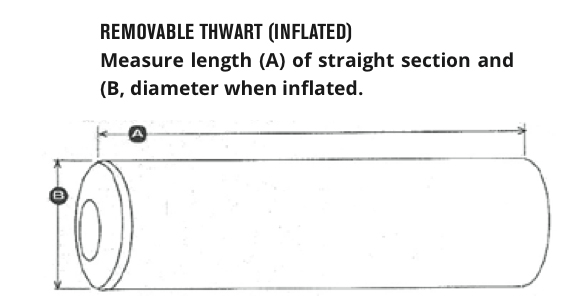

REMOVABLE THWART (INFLATED)

Measure length (A) of straight section and (B), diameter when inflated.

Since the boats are handmade, the two parts that are not normally stocked are replacement floors and thwarts (since the measurements can vary slightly). If you need a replacement floor or thwart, we need the following measurements listed in the diagram(s) below, when you place your order. The best time to order is from Late Summer to December, for delivery the following spring, if you need it by the start of the season.

Measure floors while deflated, measure thwarts while inflated.

TROUBLESHOOTING

VALVE DOES NOT RETAIN AIR WHEN PUMP IS REMOVED

VALVE DOES NOT RETAIN AIR WHEN PUMP IS REMOVED

Make sure that the center spring is in the closed/up position.

Clear any debris that might be preventing the valve from sealing. This can be accomplished by pumping quick bursts of air into the valve with the valve in both closed and open positions.

Make sure that the lock ring on the valve is tight.

TUBE BECOMES SOFT AFTER INFLATION PROCESS

TUBE BECOMES SOFT AFTER INFLATION PROCESS

Determine which air chamber is soft. Starting at the valve, spray with soapy water to find leak. Make sure the valve is functioning correctly, with no signs of leaking. (See above)

TIP: If you spray the valve with soapy water and it leaks from the outside of the valve it is either loose, the washer is upside down or the valve is off center. If it leaks from the center, something is holding the spring open.

If the leak is at the fabric, find the hole in the fabric and patch with an appropriate sized fabric patch. (See Gluing Instructions under Repair)

FLOOR BECOMES SOFT AFTER BOAT IS ON THE WATER

FLOOR BECOMES SOFT AFTER BOAT IS ON THE WATER

The cooling effect of the water will soften the floor from its initial pressure. Top off the floor again until the relief valve opens. If it becomes soft again, see process above for locating a leak, starting with the valves.

PRESSURE RELEASE VALVE NOT OPENING AT 2.0 PSI

PRESSURE RELEASE VALVE NOT OPENING AT 2.0 PSI

Remove the valve and wash it in soapy water and rinse it thoroughly. If your PRV fails to work after cleaning and properly reinstalling, replace it immediately. This could result in a blown I-beam in the mattress floor, which averages a $300 repair cost. Under the filter screen is a colored dot that indicates the PSI, so make sure it is the mfg suggested setting of either a blue dot (2.0 PSI release) or yellow dot (1.75 PSI release).

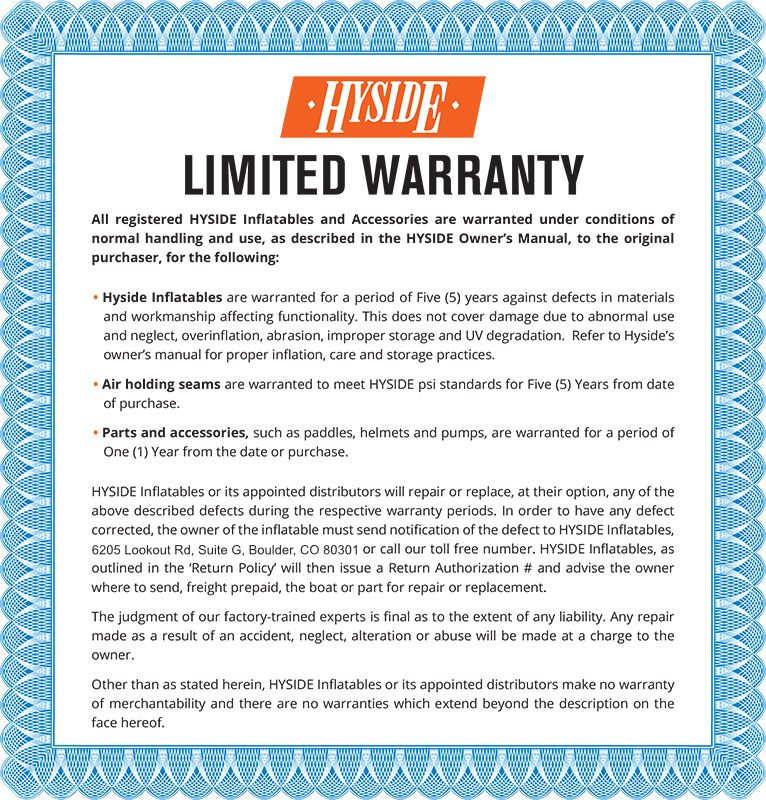

WARRANTY INFORMATION

HYSIDE’s goal is to provide you with a product that won’t leave you worrying about a warranty. Warranties won’t help you in remote locations or on the river. That said, if you do have any issues, please see the Terms and Conditions below, as well as our Limited Warranty and Limited Liability (our lawyers made us do it).

RETURN POLICY

RETURN POLICY

Any merchandise being returned for any reason, must have a Return Authorization (RA) number. Please call our toll free number, 800-868-5987, for a RA #. HYSIDE staff will guide you through some trouble-shooting techniques before issuing a RA number (we may be able to solve your problem over the phone). We will advise you where to return the item and buyer is responsible for return shipping. Any cancellations are subject to a 5-10% charge to cover processing and restocking fees.

Products are eligible for return 14 days from the date of delivery. Products can only be returned unused and in commercially resalable condition. Any products returned wet or having been wet, not in their original factory packaging or shrink wrapping are not eligible for refund. These products are only eligible to be serviced under their warranty. Special order merchandise or dropped shipped items are not eligible for return.

DAMAGED ITEMS

DAMAGED ITEMS

Damaged items or boxes must be reported immediately to the delivery driver to be reported to the shipper, in order to make a claim. If boxes are visibly damaged, we recommend opening the boxes in the presence of the delivery driver or possibly even refusing the shipment depending on condition. Our boxes are well packed when they leave our dock and all items are tightly packed. Damage is the responsibility of the freight company, but must be reported properly.

RESTOCKING FEES

RESTOCKING FEES

If products are returned unused and in resalable condition, using a RA # issued within a 14-day period of the delivery date, a 10% or $10 minimum transaction fee, whichever is greater, is charged. Returned orders that received Free Shipping will be subject to a $10 fee or the actual shipping amount, whichever is greater, to cover the cost of shipping and handling. Shipping and installation fees are non-refundable services.

Acceptance of delivery of any product constitutes purchaser’s acceptance of this agreement and subjects purchaser to its contents.

LIMITATION OF SELLER LIABILITY

Seller’s liability is as stated in the written express Limited Warranty and is expressly limited solely to the replacement and/or repair of this inflatable for defects in material and workmanship as covered by said warranty, and seller shall not be liable for any loss or damage, directly or indirectly arising from the use of this inflatable or for consequential damages (including, but not limited to, incidental or consequential damages for lost profit, lost sales or any other incidental or consequential loss). HYSIDE Inflatables does not have control of the use and/or operation of your new HYSIDE inflatable. Said inflatable has not been warranted to be fit for any particular use, or purpose, nor is HYSIDE responsible for the experience level or training of those who will use, occupy or maintain this inflatable, nor is HYSIDE responsible or liable for personal injury in connection with the use of this product.